What is a thermistor used for in a combi boiler

- Overheating protection: The thermistor is used to monitor the temperature of the water in the combi boiler, and to shut down the system if it overheats.

- Temperature sensing: The thermistor is used to measure the temperature of the water in the combi boiler, and to control the heating elements accordingly.

- Flow rate monitoring: The thermistor can be used to monitor the flow rate of water through the combi boiler, and to adjust the heating elements accordingly.

- Efficiency control: The thermistor is used to optimize the efficiency of the combi boiler by controlling the heating elements based on the water temperature and flow rate.

- Safety control: The thermistor is used as a safety device to shut down the combi boiler in the event of a fault, such as a short circuit or an over-temperature condition.

- Fault detection: The thermistor can detect faults in the heating system and trigger an alarm to alert the user.

- Energy management: The thermistor is used to optimize the energy usage of the combi boiler by controlling the heating elements based on the water temperature and flow rate.

- Hot water demand control: The thermistor can be used to control the hot water demand in the combi boiler, based on the temperature of the water in the system.

- Circulating pump control: The thermistor can be used to control the speed of the circulating pump, ensuring that the hot water is circulated evenly throughout the system.

- System balancing: The thermistor can be used to balance the hot water distribution in the system, ensuring that hot water is delivered evenly to all outlets.

How do you check if a thermistor is faulty in a combi boiler?

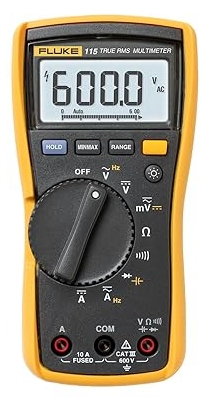

- Check the resistance: The resistance of the thermistor should be measured using a multimeter. If the resistance is significantly different from the manufacturer’s specifications, the thermistor may be faulty.

- Check for continuity: The continuity of the thermistor can be checked using a multimeter. If the multimeter does not beep when the probes are placed on either end of the thermistor, it may be faulty.

- Observe the system performance: If the combi boiler is not functioning properly, such as not heating up or overheating, it may be due to a faulty thermistor.

- Check the wiring: The wiring of the thermistor should be checked to ensure that it is connected properly and that there are no loose connections.

- Consult the manufacturer’s manual: The manufacturer’s manual may have specific instructions on how to diagnose and replace a faulty thermistor in your particular model of combi boiler.

Thermistor faults

Thermistors work in conjunction with the user potentiometer (boiler setting for temperature), and the Printed Circuit Board (PCB).

A small Direct Current (DC) is sent to the thermistor via the potentiometer, the PCB then knows whether to give more, or less gas to ensure the correct water temperature. This will depend on a small voltage drop due to the change in current.

Thermistors also indicate to come on when the temperature gets too cold (frost protection). The boiler will ignite when the resistance reading drops below a certain level. Thermistors can be used to monitor other things such as anti-scale (pump over-run).

Symptoms of faulty boiler thermistor

- Scale / magnetite deposits affecting heat transfer / sensitivity

- System water ingress (causing open circuit / infinity)

- Loss in manufacturers calibration

- Damaged terminals / connections / wiring faults

Normal resistance of a thermistor?

The normal resistance of a thermistor varies depending on the type and specifications of the thermistor. Generally, thermistors are characterised by their resistance-temperature relationship, which can be described by a polynomial equation or a lookup table. The resistance of a thermistor changes as the temperature changes, so there is no single “normal” resistance value.

The resistance of a thermistor can range from a few ohms to several kilohms, depending on the type and specifications of the thermistor. NTC (negative temperature coefficient) thermistors, which are commonly used in heating systems, have a resistance that decreases as the temperature increases. PTC (positive temperature coefficient) thermistors, on the other hand, have a resistance that increases as the temperature increases.

It is important to consult the manufacturer’s specifications for the specific thermistor being used in your combi boiler to determine the normal resistance range for that thermistor.

Two types of thermistor

- NTC (Negative temperature co-efficient)

- PTC (Positive temperature co-efficient)

NTC Thermistor

Shows a decrease of electrical resistance when the system water increases in temperature and shows an increase of electrical resistance when the system water decreases in temperature.

These decrease the resistance proportionally with an increase in temperature. For example 25oC to start at 12,000 Ohms, to 55oC at 4,000 Ohms.

As the temperature goes up, resistance comes down.

Typical starting resistances are in the range of 12-15,000 Ohms (12-15k Ohms), down as low as 900 Ohms when boiling.

PTC Thermistor

Shows an increase of electrical resistance when the system water increases in temperature and shows a decrease of electrical resistance when the system water decreases in temperature.

This is the opposite of an NTC. As the temperature increases proportionally with temperature rise. They are identical to look at as an NTC, they just behave differently.

From a 10o start at 800 Ohms, up to 90o at 1600 Ohms. They are less common than NTC thermistors.

Typical Sequence:

As the system water increases in temperature, the resistance of the NTC thermistor, decreases, and the potentiometer at the p.c.b then varies the voltage to the modureg on the gas valve, which in turn, modulates the burner accordingly, to match the demand for the heat load.

To Test a Thermistor:

- Electrically isolate boiler / system controls

- Ascertain system water temperature (near to thermistor) by using a thermal laser or clamp on thermal sensor

- Remove thermistor wires (at the p.c.b end) to prevent stray resistances from the p.c.b itself

- Set multimeter on ohms scale for resistance readings

Note: PTC thermistors only: the black lead from the multimeter must go on the metal casing of the sensor and the red lead from the multimeter must go on the terminal of the sensor. Resistance readings must be cross referenced to that of the manufacturer specification, to prove correct manufacturer calibration.

- Closed circuit of less than 1 ohm = faulty

- No resistance/infinity = faulty

An example of NTC resistance values:

| Temperature (oC) | resistance (ohms) |

|---|---|

| 0 | 35400 |

| 10 | 22500 |

| 20 | 14700 |

| 25 | 12000 |

| 30 | 9835 |

| 40 | 6712 |

| 50 | 4672 |

| 60 | 3311 |

| 70 | 2388 |

| 80 | 1749 |

| 90 | 1300 |

| 100 | 980 |

| 110 | 749 |

Graphs Representing resistance versus temperature

NTC thermistor

PTC thermistor

How to replace a thermistor in a combi boiler

- Turn off the power: Before attempting to replace the thermistor, turn off the power to the combi boiler to ensure safety.

- Locate the thermistor: The thermistor is typically located near the heating elements or the water flow sensor. Refer to the manufacturer’s manual to find its exact location.

- Disconnect the thermistor: Disconnect the wiring from the thermistor by carefully loosening the terminal screws.

- Remove the old thermistor: Remove the old thermistor by gently pulling it out of its socket or by unscrewing it from its mounting.

- Install the new thermistor: Install the new thermistor by carefully pushing it into the socket or by screwing it into its mounting.

- Connect the wiring: Connect the wiring to the new thermistor by carefully tightening the terminal screws.

- Test the system: Turn on the power to the combi boiler and test the system to ensure that the new thermistor is functioning properly.

- Check for leaks: Check the connections and the surrounding area for any signs of leaks, and tighten any loose fittings as needed.

Note: It is important to follow the manufacturer’s instructions and to use caution when working with electrical components. If you are not confident in your ability to replace the thermistor, it is recommended that you seek assistance from a qualified heating technician.

Expected Thermistor Manufacturer Readings

Resources

- What is a thermistor? (video)

- Combi boiler thermistor testing (video)

- Testing boiler thermistors (video)